CNC machining

The CNC machine is translated from English: Computer Numerical Control – Computer numerically controlled.

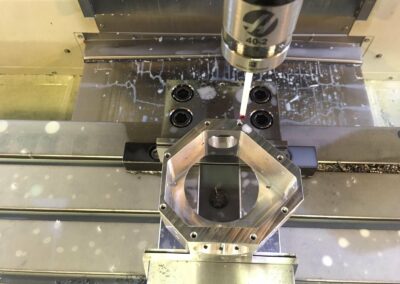

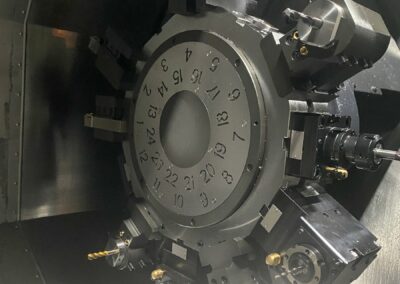

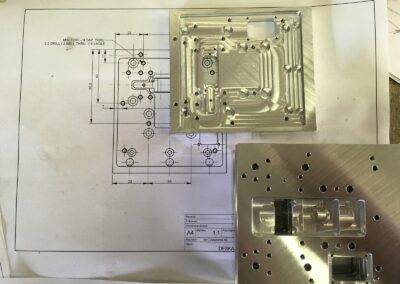

These numerically controlled machines are now an integral part of our production – turning, milling, drilling, grinding. Maximum precision and three-dimensional shapes can be achieved on these machines.

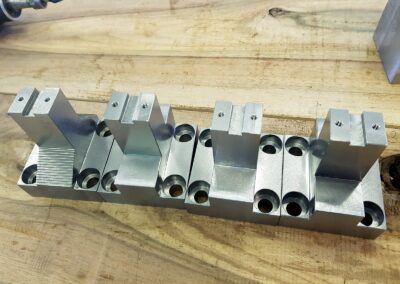

Production of technological parts according to CNC programs. Production of parts to order according to the customer’s wishes.

Conventional machining, there are still parts that cannot be produced other than on conventional machines: We turn to a diameter of 1400mm and 5000mm length max. workpiece weight 3,5t.

3D programming TECHNOLOGY

Solid Edge 3D CAD software and CAM NX12 from Siemens is a complete solution for CNC machining. The link between the control system and the machine. The use of drawing machine parts and their assemblies, such as forms etc.

We provide distortion of damaged parts and production of drawing documentation.

CNC machining is a numerically controlled machine, able to produce with high precision ensuring turning and milling at high speeds when a smooth surface is achieved, the use of mainly mold in combination with 3D programming. Furthermore, drilling, threading, circular interpolation is a matter of course for the machining center and in order to be able to control this machine numerically (feedback between the control system and the machine, drives: servo drives and stepper drives.

Production of custom parts. Home accessories, parts for motorcycles and choppers.

In the summer of 2012, we acquired Solid Edge 3D CAD software and CAM Express a complete solution for CNC machining for our CNC machining. At present, we are able to offer 3-axis shape machining, such as inserts, molds, etc. In classic turning we can offer max. turning diameter 1400mm and max. turning length 5000mm Cylinders etc.